The Technology Blog

Collaborative Robots (Cobots) and the Future of Work

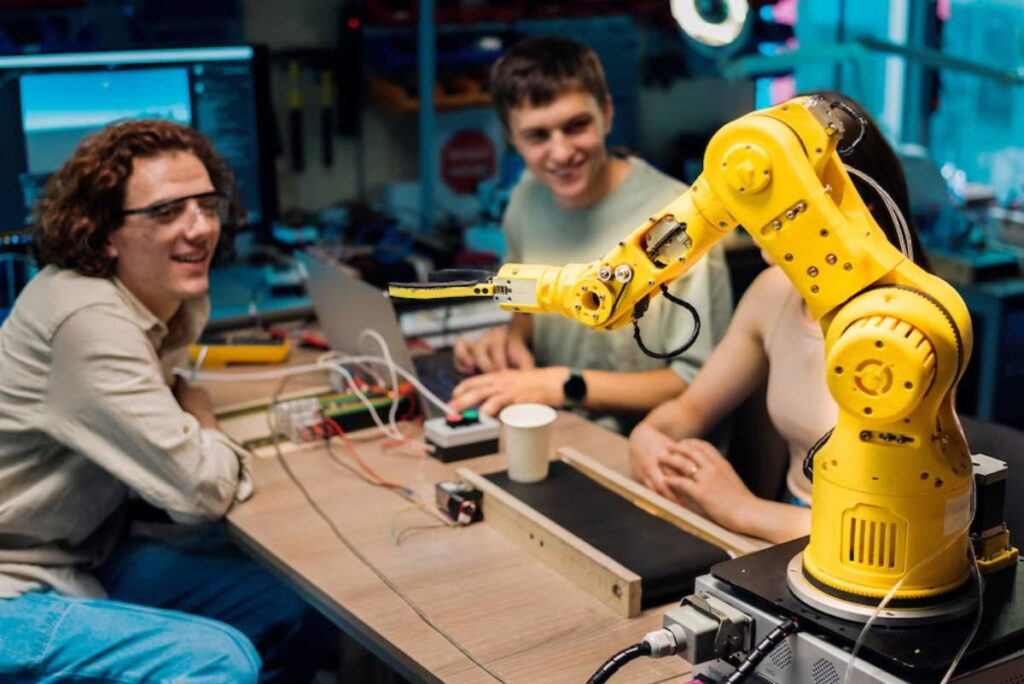

For decades, robots in the workplace looked like huge machines behind cages. They seemed isolated, powerful, and possibly dangerous. These traditional industrial robots changed the way we manufacture. Still, they operated apart from humans because of safety worries. Today, a quieter and more flexible shift is taking place with collaborative robots, or cobots.

Cobots are different from older, bulkier machines. They are made to work with humans, not separately. They’re smaller, safer, and smarter. They can learn tasks, adapt to environments, and boost productivity in many industries. As organisations consider the future of work, human-robot collaboration is now a real part of daily operations. It is changing how we work.

In this article, we’ll look at what cobots are. We’ll see how they’re changing workplaces and what this means for the future of robotics. We’ll also explore the growing bond between people and smart machines.

What Are Cobots?

Cobots, or collaborative robots, are made to work with humans in the same area. They have advanced sensors, AI software, and safety features. This lets them work alongside people without needing protective barriers.

Key Features of Cobots:

- Safety-first design: Force and speed limitations, collision detection, and emergency stop functions.

- Ease of use: Intuitive programming, often without the need for coding skills.

- Flexibility: Can be quickly reprogrammed and redeployed across tasks and departments.

- Compact size: Designed to work on human-scale tasks and fit into existing workflows.

Cobots focus on augmentation, enhancing human abilities instead of replacing them. Traditional robots mainly deal with automation.

The Evolution of Human-Robot Collaboration

The concept of human-robot collaboration has matured significantly. Cobots were first used in industrial automation. Now, they also help in logistics, healthcare, agriculture, retail, and hospitality.

Milestones in Cobotics:

- 2008: Universal Robots introduces the UR5, one of the first commercially successful cobots.

- 2011–2020: Big car makers and electronics firms start using cobots. They aim to boost assembly line safety and efficiency.

- Today: SMEs (small and medium-sized enterprises) are using cobots more. This is because costs are dropping and they are easy to set up.

Cobots are moving robotics from large factories to everyday workplaces.

Key Benefits of Cobots in the Workplace

1. Enhanced Worker Safety

Cobots handle repetitive, risky, or tough tasks. This cuts down on workplace injuries and fatigue.

A cobot in a warehouse lifts heavy items. This helps employees avoid back strain.

2. Increased Productivity and Quality

Cobots increase quality and minimise errors by performing exact tasks and repetitive jobs. They don’t need breaks or downtime.

Higher efficiency without sacrificing craftsmanship.

3. Job Enrichment and Reskilling

Cobots let workers focus on more complex, creative, or supervisory tasks. This boosts job satisfaction and helps develop skills.

Most cobots don’t replace humans. Instead, they support them. They turn line workers into robot operators or quality controllers.

4. Cost-Effective Automation

Cobots are usually cheaper and simpler to set up than traditional robots. This makes them available for businesses of any size.

Lower integration costs and quicker ROI encourage trying new things and growing.

5. Adaptability in Uncertain Times

Cobots help keep operations running during disruptions like pandemics or supply chain issues. They also assist in meeting new safety standards.

During COVID-19, cobots were quickly used in food production. They helped meet demand and allowed for social distancing.

Applications Across Industries

Manufacturing

- Assembly, welding, and quality inspection

- Delicate tasks like electronics handling

- Co-working with technicians on complex builds

Logistics and Warehousing

- Picking, packing, and palletising

- Collaborative inventory management

- Integration with AGVs (automated guided vehicles)

Healthcare

- Supporting surgery or rehabilitation therapy

- Assisting staff with logistics in hospitals (e.g., medication or supply delivery)

- Sanitisation and disinfection tasks

Retail and Customer Service

- Inventory shelf scanning

- Greeting customers or answering queries

- Preparing food or beverages in quick-service environments

Agriculture

- Harvesting soft fruit or vegetables

- Monitoring soil and crop conditions

- Sorting and packaging fresh produce

Takeaway: Cobots can help with repetitive, precise, or hard tasks.

Cobots vs. Traditional Robots: A Quick Comparison

| Feature | Cobots | Traditional Robots |

| Work Environment | Shared with humans | Isolated (caged) |

| Programming | Intuitive, no-code or low-code | Complex, requires specialists |

| Flexibility | High—easy to reconfigure | Low—fixed tasks |

| Cost | Lower upfront and integration costs | Higher setup and maintenance costs |

| Safety Features | Designed for direct human interaction | Requires physical safety measures |

Conclusion: Cobots are the solution when automation is needed but a complete robot upgrade isn’t practical or affordable.

Challenges and Considerations

Despite their promise, the adoption of cobots isn’t without hurdles.

1. Integration Complexity

Cobots are simpler to set up than traditional robots. However, they still need careful integration into current workflows.

2. Workforce Resistance

Some employees fear job loss or may be reluctant to work alongside machines.

Solution: Involve staff in cobot training and implementation to foster trust and transparency.

3. Safety Perception

Though cobots are designed to be safe, concerns remain about human error or misuse.

Solution: Regular safety audits and user training can reinforce secure interactions.

4. Regulatory Uncertainty

Labour laws and safety standards for cobots are still evolving in many regions.

Solution: Organisations must stay updated on compliance guidelines, particularly in heavily regulated industries like healthcare or aerospace.

The Future of Cobots and Human-Robot Collaboration

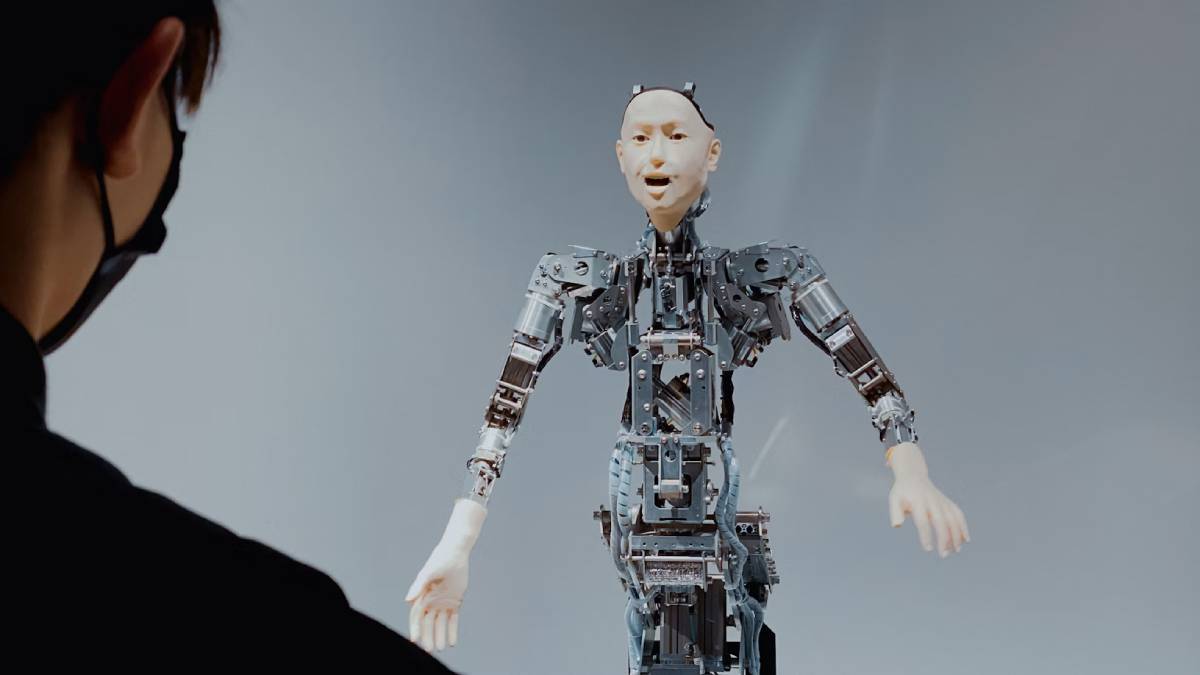

As AI advances, cobots will become increasingly autonomous, intelligent, and responsive. The future of human-robot teamwork is all about smooth, real-time interaction between people and machines.

Future Trends:

- Voice and gesture control for intuitive commands

- Context-aware cobots that adapt to changing environments and team dynamics

- Remote monitoring and predictive maintenance using IoT integration

- Emotionally intelligent cobots for roles in care, education, and customer service

In tomorrow’s workplace, humans and cobots will work together. They will also create, solve, and grow as a team.

Building a Cobot-Ready Workforce

To get the most from cobotics, companies should encourage a culture of innovation and learning.

How to Prepare:

- Invest in training: Upskill employees in robotics literacy, programming, and human-machine interface design.

- Redesign workflows: Incorporate cobots into value-added roles that empower human workers.

- Include everyone: Make sure all employees, no matter their age or background, are part of the transition.

Ethical consideration: Cobots should be seen as tools for empowerment, not displacement.

Working Smarter, Together

Cobots represent a pivotal shift in the evolution of the workplace. They create smarter, safer, and more collaborative environments. This combines automation’s precision with human creativity. To address the challenges and grab the chances in robotics, we need to accept human-robot teamwork. This approach will help us create industries that are sustainable, resilient, and inclusive.

Act now! If you’re an SME exploring automation or a professional curious about the future of work, learn how cobots can boost your workflow and support your growth